- Procure Nerds

- Posts

- Weekly Special - The Myth of the Procurement Plan B

Weekly Special - The Myth of the Procurement Plan B

Why most backups collapse under pressure — and how to build one that actually works

Howdy fellow nerds -

This week’s special focuses on the myth of the “Plan B” in procurement — and why most backups collapse the moment you actually need them.

How many times have you heard : “Don’t worry, we’ve got a Plan B.”?

And how many times have you seen how useless they really are? Because most “Plan Bs” aren’t worth the PowerPoint they’re written on.

They look fine in a steering committee.

They sound confident when you’re pitching risk management.

But the minute a port shuts down, a typhoon hits, or your supplier stops answering emails, those Plan Bs collapse into panic sourcing.

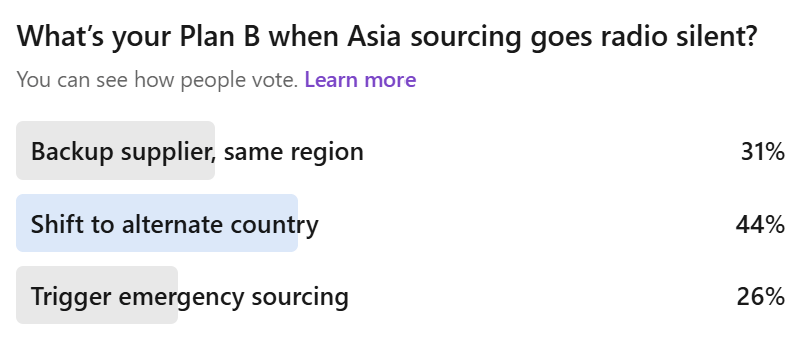

Last week I asked you what your Plan B is when Asia sourcing goes radio silent. The poll results looked neat:

Here’s the problem: all of these are still Plan As. Just with a different label.

And when reality bites, that’s not good enough.

So let’s deep dive on what a real Plan B looks like - and how to build one before you need it.

Case 1: Switching Countries

It feels like the boldest move. China shuts down? Go Vietnam. India stumbles? Go Malaysia.

But it’s a reset button:

New lead times.

New compliance checks.

New cost structures.

At the exact moment when you’ve got neither patience nor budget for resets.

What to actually do:

Set up dual-country sourcing before you need it.

If you rely on South China, divert at least 15–20% of volume into Eastern Europe or Mexico now.

That way when disruption hits, your “alternate country” is already part of your supply chain.

Case 2: Same-Region Backups

A second supplier in the same region feels like insurance. But they share the same risks: strikes, tariffs, typhoons.

Remember Shanghai’s 2022 lockdown? Companies with “backups” in Jiangsu discovered their suppliers were also paralyzed by closed highways.

What to actually do:

Think regional diversification, not city clustering. South China + Thailand. Northern India + Vietnam. Backups need to live outside the same blast radius.

Case 3: Emergency Sourcing

The adrenaline shot. Quick, dirty, expensive.

When one global tech firm needed 300 laptops overnight during COVID chaos, they paid a 42% premium.

It fixed the crisis, but procurement was branded “too expensive” for months.

What to actually do:

Keep a shortlist of pre-negotiated emergency suppliers.

Yes, you’ll still pay extra, but at least you cap the damage instead of bidding against desperation.

So, what’s a real Plan B?

Signed contracts with suppliers who already get some of your volume.

Tooling and documentation ready, not theoretical.

Regular stress tests to see who actually picks up the phone.

Clear governance on when to flip the switch.

If you’re still asking “what now?” when disruption hits, it wasn’t a Plan B. It was a bedtime story for your steering committee.

Procurement isn’t about writing contingency slides. It’s about building leverage you can activate.

So here’s my challenge to you:

When was the last time you stress-tested your Plan B — instead of just writing it down?

Want to go deeper?

I built a full Asia Risk Playbook that maps out country-by-country risks, sourcing blind spots, and practical backup strategies for buyers who don’t want to scramble when things break.

👉 Grab your copy here: Asia Risk Playbook on Gumroad

Stay nerdy, and remember — the only good Plan B is the one you’ve already tested.

Until next time,

Zvi